What is a Returnable Asset?

Returnable Asset are physical items or containers that can be reused multiple times within a supply chain, being returned to their point of origin after each use. These assets are essential for transporting items such as equipment or inventory, although they are often undervalued in terms of their actual worth.

In reality, returnable assets can become quite expensive if they are frequently misplaced or lost. Common examples include pallets, bins, containers, totes, and packaging materials.

These assets play a crucial role in reducing waste, increasing efficiency, and cutting costs in the supply chain. However, to ensure their effective reuse, it is necessary to implement robust tracking and management systems.

Why are Returnable Assets Important?

Returnable assets are fundamental to the efficient storage and transportation of valuable items. Even though they themselves might not hold much intrinsic value, the items they carry are often critical to business operations.

Therefore, losing visibility of a returnable asset can mean losing visibility of more crucial assets. This can lead to significant financial losses if several returnable containers are misplaced or not returned. Effective tracking of these assets can prevent major profit losses.

Returnable assets allow businesses to streamline their supply chain operations. By using these reusable containers, companies can avoid the high costs associated with single-use packaging, leading to overall cost savings. Moreover, the environmental impact is reduced as there is less waste generated, aligning with sustainability goals.

Returnable Asset Tracking Technology

Tracking technology for returnable assets can greatly enhance their management and utilization. Solutions provided by companies like ifm include a range of capabilities:

- Long-range communication: This allows tracking of assets that are out of sight, ensuring that even those assets that are not immediately visible can be monitored.

- Short-range communication: This is useful for automated tools and systems, providing detailed tracking within a smaller area.

- Effortless integration: Tracking systems can be integrated with single read points, making it easier to manage and track assets.

- Gate tracking and cloud technology: This offers comprehensive tracking solutions that utilize gates to monitor asset movement and cloud technology for data storage and analysis.

The result of implementing such technology is a comprehensive system that tracks returnable assets throughout their entire lifecycle. Real-time location tracking and validation of returnable assets help establish lean logistics operations, making it possible to locate assets quickly and ensure they are being returned and reused as intended.

The Cost of Not Tracking Returnable Assets

Failing to track returnable assets can result in substantial financial losses. It is estimated that up to 40% of returnable assets disappear annually without a clear reason. This can have a significant impact on a company’s bottom line. For instance, a single $20 pallet may not seem important compared to the valuable inventory it carries.

However, repeatedly having to replace these pallets due to negligence can lead to significant costs. In some cases, restocking returnable assets can cost up to $5000.To mitigate these losses, companies often purchase more reusable assets than needed to ensure they have enough to meet demand.

However, this approach ties up capital that could be used elsewhere. By employing a real-time location system, businesses can maintain the perfect amount of reusable assets, knowing exactly where they are and how they are being used at all times. This improves cash flow management and reduces unnecessary expenditure on additional assets.

Effects on the Supply Chain

Returnable assets are essential for the smooth operation of supply chains. Misuse or misplacement of these assets can create significant bottlenecks, impacting overall efficiency. Key issues include:

- Misplacement: Without a clear understanding of how assets are lost or underutilized, improving their use becomes challenging.

- Accountability: Proper accountability mechanisms are needed to ensure that returnable assets are used efficiently.

- Shipping and Downtimes: Returnable assets play a crucial role in throughput. Effective tracking reduces the time spent searching for assets in warehouses, leading to faster shipping times and reduced downtimes.

By tracking returnable assets in real-time, businesses can ensure that these assets are neither underused nor misused, thereby enhancing supply chain efficiency.

The Value of Tracking Returnable Assets

Tracking returnable assets offers significant value. Instead of tracking each individual item on a pallet, placing a tracker on the pallet itself can streamline the monitoring process. This method provides a more efficient way to track assets, ensuring their optimal use and reducing the likelihood of loss or misplacement.

Affordable tracking solutions like AirFinder offer real-time visibility of returnable assets, solving the problem of cost-inefficiency associated with traditional expensive asset tracking systems.

Reliable Methods for Monitoring Returnable Assets

Several technological solutions are available for tracking returnable assets, each with its own advantages and limitations:

Bluetooth: Bluetooth Low Energy (BLE) tags can be used to track returnable assets with high precision. These tags communicate with mobile and fixed gateways, making indoor tracking efficient. However, Bluetooth has a limited range, which can lead to inaccuracies if assets move too far or too quickly.

RFID: RFID tags, or smart labels, use unique serial numbers to identify returnable assets. These tags are read by fixed-point readers, providing reliable tracking within specific areas. However, RFID systems are limited in their ability to track assets in real-time during transportation without costly additional infrastructure.

GNSS: Global Navigation Satellite System (GNSS) technology offers precise worldwide tracking using satellites. This system is ideal for monitoring assets outdoors but is less effective indoors due to signal shielding, which can reduce tracking accuracy.

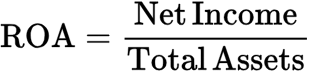

Return on Assets Formula

Although there are several methods to calculate return on assets (ROA), it is typically determined by dividing a company’s net income by its average total assets. To find the average total assets, add the ending total assets of the previous period to the ending total assets of the current period, then divide the result by two.

Conclusion

Tracking returnable assets is essential for maintaining an efficient and cost-effective supply chain. The right tracking solution depends on the specific needs and operations of the business. Factors such as the cost of installation, the value of the assets being tracked, and the operational environment must be considered when choosing a tracking system.

Digital tracking solutions can significantly enhance the management of returnable assets, ensuring they are used to their full potential and returned as intended. This not only reduces operational costs but also improves overall supply chain efficiency.

Frequently Asked Questions

What is the best way to track returnable packaging?

The most recent technological solutions for tracking returnable packaging include Bluetooth, RFID, and GNSS. Each of these technologies offers different advantages and can be chosen based on specific requirements and constraints.

What are some examples of returnable assets?

Examples of returnable assets include crates, bins, boxes, and pallets. These packaging materials are designed to be reused multiple times within the supply chain, providing a cost-effective and sustainable solution for transporting goods.

What is the difference between a returnable asset and an expendable asset?

Returnable packaging can be reused multiple times during the supply chain, making it a cost-effective and sustainable option. In contrast, expendable packaging is designed for short-term use and has a lower upfront cost but cannot be reused, leading to higher long-term costs and environmental impact.